Making real sea glass at home is easy- and the process uses hobby supplies you may already have. While it takes a bit of patience, in this article I’ll show you how to make stunning sea glass gems using recycled glass. Here’s a quick roadmap of the process:

- You’ll find a short summary of the process followed by a detailed tutorial.

- A guide to the supplies needed and my best tips for finding glass to turn into sea glass,

- Answers to the most commonly asked questions about homemade sea glass.

The following section may contain affiliate links. As an Amazon Associate, we earn from qualifying purchases.

Disappointed with the spray-on version of DIY’ing a sea glass finish, I wondered, could I make my own frost glass baubles using broken bottles and a rock tumbler? Spoiler: YES. Keep reading to learn my method for making your own sea glass.

So, Can you DIY Real Sea Glass?

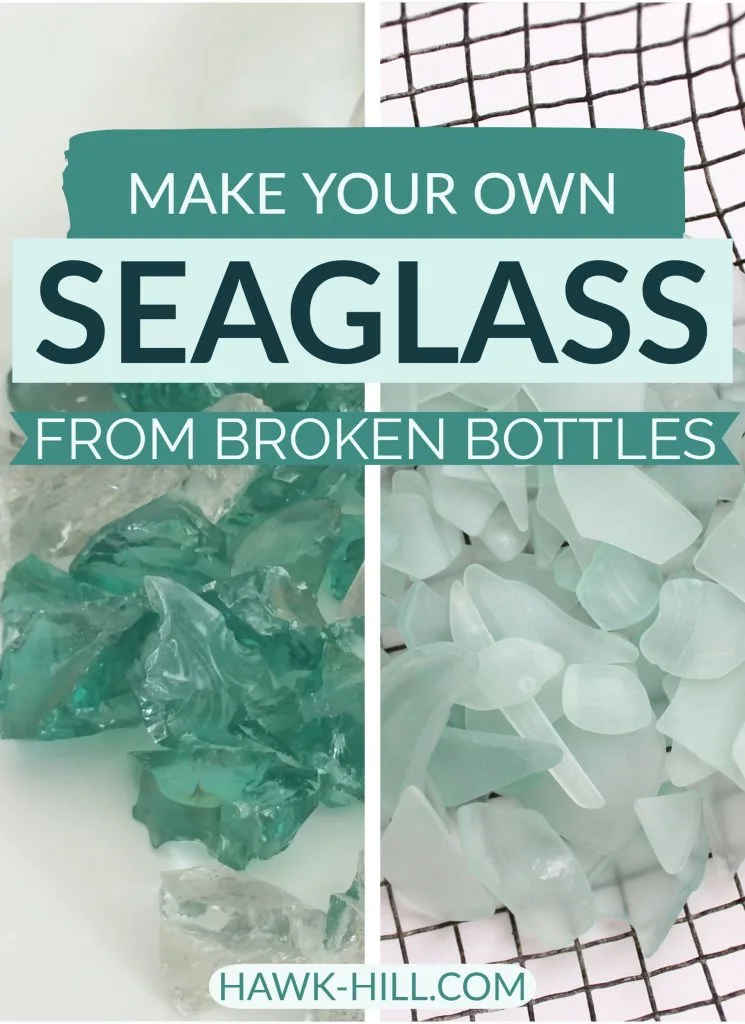

As you can see in the image below, the finish on the finished glass is frosty and matte. In every way it’s just like sea glass picked up on a beach. With this method you aren’t creating a faux sea glass finish- you’l be making the real thing! A rock tumbler prepared with these instructions creates an environment that forms real sea glass gems in the same way the ocean does!

Making Sea Glass in a Rock Tumbler

It turns out, making sea glass in a rock tumbler was way easier than I expected. For my first batch, I simply used a few tablespoons of sand. After a few days, I didn’t have sea glass- more like glass shards with slightly-less sharp edges. Determined, I then purchased a pack of carbide grit to try.

I found that using harder, coarser grit sped up the process of making glass shards into beach glass. Carbide grit, I learned, also gave me more control over how round and frosty these gems turned out.

Supplies You’ll Need:

- Motorized Rock Tumbler – I use a Leegol 3lb Capacity Tumbler for fast, professional results. Budget-conscious DIY-ers should be able to get the same results with a kids’ rock tumbler and some patience.

- Glass (see below for tips on finding good glass to tumble. For hard-to-find colors, you can buy the colored glass chunks made for high-end firepits in red, black, and colbalt blue, )

- 5-gallon bucket

- 2 large thick plastic bags (clothing storage bags work great)

- a fry basket or a colander with big holes (fry baskets are perfect for sorting tiny glass fragments out from usable sea glass pieces)

- cut-resistant work gloves

- safety glasses (seriously, do not attempt this project without safety equipment)

- hammer

- shallow cardboard box (to contain small shards of glass)

- grit (you can use sand, but a coarser grit gets the job done with less time and electricity. If you think you might also tumble rocks, try a variety pack of abrasive media. For just making a few batches of broken glass into sea glass, you can buy coarse abrasive media in 1lb packs.

First, a Simple Walkthrough of How I Make Sea Glass:

(or click here to jump to the detailed guide)

How to make sea glass

Total Time: 3 days

Find or Make Broken Glass

Source glass from thrift stores, recycling, or garage sales. Read my tips for sourcing colored glass.

Tumble

Use the instructions below for replicating the ocean’s sea-glass making environment in a rock tumbler

Sift and Clean

Separate glass from grit using a water and a colander

Create or Display

With your finished sea glass, you can create artful beach glass crafts and creations, like this beach house inspired sea glass pendant light.

Supply:

- Protective Gloves

- Safety Goggles

Tools:

- Rock Tumbler

- Colander

Materials: Broken Glass Carbide grit or sand

Detailed Tutorial: How to Make Sea Glass

Step 1: Find Glass

Depending on how picky you are about color and thickness, acquiring the glass to make into sea glass can be the easiest or the hardest part.

Sources for colored glass:

- your own recycling

- yard sales

- recycling centers (although unusual, some will allow you to pick from donated glass)

- thrift stores

- garage sales

Wine bottles and liquor bottles can be used for making sea glass, although in my experience only the glass at the upper rim of the neck and the bottom of the bottle is thick enough to make pieces of sea glass that are substantial in size.

Recycling Center – this is by far my best source for good glass pieces to turn into glass gems. In Joplin, the main recycling center features huge open bins where glass is collected until it is hauled away once a week. Since re-purposing is the lowest-impact form of recycling, ask your recycling center if you can take glass for free. Joplin’s recycling employees were happy to provide bags for me to take all the bottles and jugs I wanted.

The recycling center gives me access to lots of different types of bottles. High-end liquor bottles and vintage glass pieces tend to be made from thicker glass and make great sea glass.

My BEST colored glass results were achieved using old telephone insulators. When I decided to smash an already-cracked, aqua-colored glass insulator, the resulting sea glass was a gorgeous blue-green color that created beautiful, thick stones of manufactured beach glass. (I’ve since discovered you can get the same result by tumbling the coarse stones of colored glass made for decorative fire pits, they even have glass stones in this vintage turquoise shade)

Step 2: Break Glass

This is by far the most dangerous part. Please be smart, safe, and glass savvy. Glass is pointy and dangerous, handle with extreme caution and with all appropriate safety equipment. And for the love of your eyeballs, do not skip protective eyewear.

A. Have the barrel of your tumbler open and nearby. Place the unbroken glass in a heavy plastic bag, then place that bag into another heavy plastic bag. Put on goggles and gloves and place the bagged object inside a cardboard box.

B. With goggles on, use the flat side of the hammer to strike the object until it breaks. Continue striking the large pieces until the pieces are somewhat uniform in the size range you desire for your sea glass products (remember, tumbling will make pieces a bit smaller!).

C. Carefully, with hands protected by cut-resistant gloves, dump the contents of the plastic bags into your colander or egg basket (over a safe receptacle). Tiny shards of glass will fall through the basket leaving the big chunks behind. (When I do this part, I work over a double-bagged trash can, to minimize cleanup) Gently shake the basket of glass till the small shards are removed, then with gloved hands manually move the larger chunks of glass into the barrel of the rock tumbler.

Step 3: Turn Broken Glass into Sea Glass.

Now is the fun part!

A. Add glass until the barrel of your tumbler is about 1/2 to 2/3 full of glass (I usually fill to 2/3rd of the way full) If you don’t have enough glass shards, you can add a few clean rocks. IMPORTANT: The 1/2 – 2/3 fullness is required for the contents to tumble instead of slosh.

B. Check the manual for your tumbler, but for my 3lb capacity tumbler, I used about 3-4 tablespoons of grit. The coarse silicon carbide grit I linked earlier makes the process go about twice as fast.

C. Add enough water to cover the glass and abrasive but DO NOT OVERFILL. (You want a sludgy tumble with each barrel turn, not a constant slosh)

D. Run for 3-5 days. After 48 hours you can pop the barrel open and take a look if you are impatient like me. At this point, you should notice some frosting on the glass and significant dulling of sharp corners. Continue tumbling until the pieces are evenly frosted with rounded edges. The longer you tumble, the more the final glass pieces will have the appearance of being very, very old sea glass gems.

Step 4: Cleaning and Finishing Homemade Sea Glass

After a few days, your glass will be ready. To finish each round of tumbled glass, I hold my fry basket/colander over a bucket and gently pour the newly made frosted glass baubles from the tumbler’s chamber into the basket, allowing the water and grit to drip through leaving only the glass behind in the basket.

Take your egg basket, glass, and bucket to an outdoor area with a hose and hose down the sea glass, washing away all remaining grit and any grime picked up in the polishing process. (Do not wash the grit down your drains!)

TIP: Reuse the (kinda expensive!) carbide grit by leaving the bucket of rinse water to sit for a few hours. Once the grit settles at the bottom of the bucket, you can carefully dump off the water and save your grit for reuse.

Reader Comment TIP: [2023 article update] Stained Glass Artisans – I recently received a comment (below) from someone who specializes in creating stained glass artwork (what a cool thing to do!). They had the clever idea / suggestion of reaching out to local stained glass artists in your community to see if they have scrap glass, which will likely include many not-so-common colors. Please let me know below if you try this out – I’d love to hear about it!

Spread your homemade glass gems on a clean, dry surface to dry (a towel or a cooling rack from your kitchen works great). Once completely dry, your sea glass is ready for any project you have planned for it!

Tumbling colored glass: some tips on sourcing

Red, purple, orange, and aqua sea glass are all very rare to find on beaches as real sea glass. It turns out, manufacturing these colors in a rock tumbler is difficult as well! During the height of my sea glass-making phase, I scoured thrift stores, recycling centers, and garage sales for colored glass. Red, purple, yellow, green, and all other colors of decorative glass were easy to find and I was excited to turn them into colored sea glass – but that’s when I got my surprise…

It turns out, much of the “colored glass” that is used in decorative vases, drinkware, and figurines is colored by a pigmented coating on the outside of the glass. As soon as these colored glasses are broken, you can see the color variation from the surface to the inside of the glass. Once placed in a tumbler, the carbide grit quickly scours all the pigment off the surface of the glass, leaving plain white sea glass behind in the tumbler.

How to tell if a colored piece of glass is coated or actually pigmented glass? Check the bottom of the piece- usually, if the surface treatment has been applied there will be evidence on the bottom. Look for a clear mark where the pigment ends, drips, or varies in color. The vast majority of colored glass I found via garage sales and thrifting was, in fact, not colored glass.

You may have to look much harder to find authentic colored glass that you can put in your tumbler to get rare colors of sea glass. I had success with antique insulators, and to get that elusive red glass you may even have success going to auto salvage yards to score old warning lights and turn signals. You can also buy chunks of pigmented glass (including ultra-rare black glass), made for fire tables, which you can make into sea glass.

Conclusion

Homemade sea glass is beautiful for home decor, jewelry, fused glass art, dramatic light fixtures, and I’ve even used it in mixed media epoxy resin pieces with a lot of success.

What will you do with your sea glass? I’d love to hear your questions, comments, or stories about how this technique worked for you!

Thanks for Reading!!!

I hope you can tell that I love DIY, researching the best affordable solutions for every-day problems opportunities and documenting / sharing solutions!🙌 Hawk-Hill.com is reader-supported.

☕ Hawk-Hill.com is reader-supported. If this article saved you time or money, please consider donating $1 to help me cover the cost of hosting this website OR If you appreciate this information and want to throw a “Thanks!” my way by buying me a coffee – I would Of Course appreciate it! :]

Reader Questions and Recommendations

Readers, do you have any favorite topics / posts? What would you like to read more about in the future? As I hope you can tell from this and other articles on my site, I really enjoy DIY / a good challenge, and I’m not afraid to roll up my sleeves to figure out a great, and hopefully simple 😁 solution. So please feel free to let me know in the comments below (or reach out via social media)!

Ok Really – I’ll try to wrap this up now😂

Finally, if you’d like to continue to learn about interesting DIY options as well as how YOU can tackle creative new projects consider checking out the latest and most popular articles listed on the Hawk-Hill Home Page. I’m always trying to enjoy and write about the creative side of life so please don’t be a stranger – check back often!😍

If you enjoyed this post you may also enjoy reading / perusing / devouring😊 one or all of these articles as well!

- 💡4 Easy Steps to Make Your Own Sea Glass 🌊

- ❤️Bedroom Decorating Ideas for Single Women’s Master Bedrooms 🛏️

- 🏡Ikea Kitchen Cost: What I Spent for a 9×12 Kitchen Remodel 💵

- 3 Simple Ways to Make a Sea Glass Light: Pendant, Lamp, or Nightlight

- DIY: My Method for Painting an Antique Gold Patina Finish on Frames

Pin it now to find it later:

Frequently Asked Questions about DIY Sea Glass

Can I use broken glass to make sea glass?

YES. You can use broken glass from just about any source for this project. If you found this article while teary-eyed over a sentimental glass vase or even a ceramic plate you just broke, this is a beautiful way to repurpose the broken pieces of glass in a way that you can enjoy and appreciate for many more years. Even if you aren’t an artist, sea glass can make an elegant display dropped into the bottom of a clear glass vase. And broken plates with sharp edges removed make beautiful mosaics or stepping stones.

Can I make sea glass with a kid’s rock tumbler?

YES. This method works by harnessing time and friction. Professional tumblers and carbide grit offer lots of friction and can finish sea glass in as little as 48 hours. If you use a cheaper kid’s tumbler and/or sand, you’ll get a lot less friction- but if you have time to wait, you’ll still be able to create finished sea glass by running the tumbler for much longer (7-10 days).

How can you tell the difference between real sea glass and tumbled sea glass?

When done well, you can’t tell the difference! The tumbling method is literally using the exact same physics to create an identical effect on glass.

However, In my experience, both as someone who has tumbled many bathes of glass and someone who enjoys a lot of beachcombing in the Pacific Northwest, “real” sea glass often has pits and uneven spots that generally are not present in tumbler-manufactured sea glass. This isn’t necessarily a good indicator, though, because even this is very dependent upon the body of water that produced the sea glass. For example, in areas of the world with roaring, churning seas, and soft sandy ocean bottoms, very round, evenly worn sea glass could certainly wash up on the beach.

Can you drill holes in sea glass?

You can, but you’ll need a special drill bit that is diamond coated (don’t worry- they aren’t a fraction as expensive as they sound!). This ultra-hard drill bit is capable of drilling through glass. You’ll want to use medium to light pressure, to prevent breaking glass, and I personally have had better luck with a higher speed drill, like a dremel tool. You’ll need to keep the drill bit and your piece of sea glass from overheating. Follow the instructions that came with your glass cutting drill bit, as you may need to work under running water to prevent overheating and glass shards from going airborne.

Can you make a sea glass without a tumbler?

Traditionally, beach glass is made with naturally tumbling – the natural motion of the ocean and the friction where water meets sand naturally churns broken glass into sea glass over time. Without a rock tumbler to replicate this process, there really aren’t any effective ways to make real beach glass. What you can do instead, is used sea glass spray paint to create a similar, though not quite the same, finish.

Can you DIY beach glass by shaking a jar?

Can Sea Glass be manufactured in bulk?

Yes! While this tutorial covers a simple process for making a small batch of sea glass, the same process can be replicated inside of a cement mixer! The cement mixers’ high-capacity makes it possible to create a massive amount of faux sea glass in one batch- although it may be more difficult to preserve large pieces of glass, due to the pressure generated inside the mixing drum

With this higher capacity and manufacturing, you can create large quantities of tumbled glass which can enable a much wider variety of craft projects. While small-batch glass is perfect for making jewelry, home decor, or beach-inspired lighting, with a cement mixer you can create buckets of sea glass at a time, which you can then use for outdoor garden projects, setting into cement for dramatic sidewalks and walkways, and even using a binder to create dramatic sea glass embedded furniture or tables.

Rhonda

Monday 18th of March 2024

I have several pieces of picture frame glass. Can this be turned into sea glass or is it too thin?

Lindsayanne Brenner

Friday 22nd of March 2024

Yes, it can definitely be turned into sea glass....pieces will likely be thin when complete but very doable!

Stacey

Monday 11th of March 2024

Great tutorial. But this isn't "real" sea glass or beach glass. This is tumbled glass. For those of us that search the shores (I live near Lake michigan my glass is beach glass. ) the hunt is what we treasure really. I do encourage you to re word your blog. And hope no one tries selling tumbled glass as the unique beach or sea glass us glassers spend time searching for. I don't discredit tumbled glass, it is a great way to get tumbled glass when you do not live near large water. Your tutorial is spectacular and very detailed! Thank you for sharing.

Ariel

Sunday 17th of December 2023

It's not real sea glass if you make it in a tumbler. It's fake sea glass.

Peggy

Sunday 5th of November 2023

Hi can I use just any sand . And do I use water .

Violent

Sunday 23rd of July 2023

Loved your no nonsense guide to tumbling.I’ve been collecting sea glass for years.Lately I’ve been looking in second hand stores…I’ve found old red,teal,purple and pink glassware…..can’t wait to plug the tumbler in.

Lindsayanne Brenner

Wednesday 26th of July 2023

Oooh, sounds awesome! I'd love to see how the results look from your rare glass!